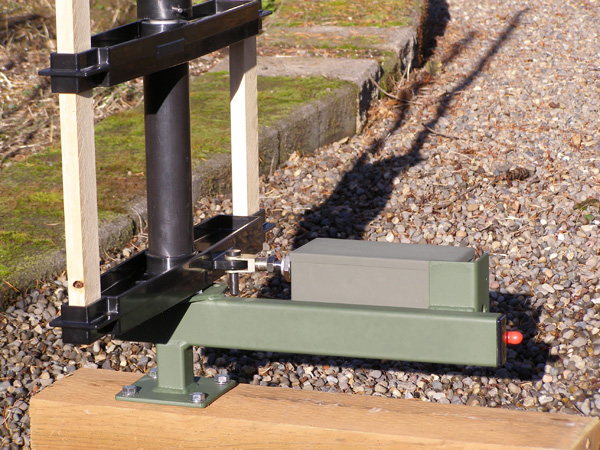

The Compact Base Wireless Turning Target has a very small footprint and is intended for fixed use in situations where space is limited. It may be mounted on several types of foundation material, and is particularly well suited to installation on wooden surfaces such as railway ties or to a treated beam bolted to a standard concrete surface.

We generally recommend the Compact Base Wireless Turning Target for permanent, or “fixed”, installations as it has the advantage of a small footprint and a wider variety of permanent mounting options. If there is a chance the frames will be unbolted from the mounting surface and temporarily used in a portable setting, then we recommend the Cross Base Turning Target.

Technical specifications

Design features

- Tough construction ensures low maintenance and permits year-round outdoor operation. SPTargets has many targets that have been in use permanently out-of-doors for 6 years or more with no maintenance.

- Low profile reduces accidental bullet damage.

Industrial plastic bearings between the moving parts remove the need for periodic lubrication. This is of particular benefit in dusty environments where lubrication of bearing surfaces is actually detrimental. - The steel components of the targets are protected by a very tough, powder-coated paint finish. The paint color is available in our standard military matte green or in a “safety yellow” finish.

- The target uses our extremely strong and durable injection-molded filled nylon rotating target frame. This target frame reduces the possibility of ricochets and it is inexpensive to replace when damaged.

- The rotating target frame can be used with standard, hardware store, wooden target supports that allow the use of regular cardboard or plastic sheet target backings.

Operational features

- Each target is independently controlled. This feature permits a wide range of target system movements that cannot be performed by “master/slave” designs used in some competing systems.

- The major target components can be replaced by the user on the target line thus reducing down-time if a target should be damaged and also avoiding the expense of requiring a manufacturer’s site visit.

- Base and module support extension - 1 x 2 inch steel tube of 0.09 inch wall thickness.

- Various steel brackets welded to the base vary between 0.125 and 0.186 inch thickness.

Pivot shaft – 0.75 inch diameter by 0.125 inch wall thickness steel DOM tube with a protective finish. - Turning frame – Extremely tough, computer-designed, injection-molded, filled nylon.

- Air system components – stainless steel, brass, anodized aluminum or plastic, inherently corrosion-resistant.

Bearings

- All bearings are self-lubricating and require no maintenance.

- Replaceable, industrial nylon bearings press-fitted into the rotating frame tube.

- Replaceable, industrial nylon bearing between the target base and the rotating frame.

- Air module bearings: Industrial nylon pins secure the air module to the rotating target frame and the metal target base.

Air Module

- All air module components are mounted inside a powder-coated steel box to protect against damage and deterioration.

- An air filter mounted inside the air module protects the pneumatic system from contamination.

- The air module is secured to the target base by two quick-release spring-clip assemblies, allowing rapid replacement of the module in case of damage.

- The air module box provides attachment points for the air and electrical quick-release connectors.

Power requirements

- The target requires a compressed air supply to power the pneumatic system. An air pressure of 55 psi is recommended, however the target will operate at any compressed air pressure from 20 to 90 psi.

- The target requires an electrical signal connection from the control system receiver.

- Target movement uses 3 cubic inches of air per cycle, permitting 10 targets to operate from a small compressor and 20 targets to operate from a medium sized compressor.

- Turning force of the rotating target frame is 60 inch pounds at an air pressure of 55 psi.

- The target operates from 12 or 24 volts DC supplied from the control system receiver. Typically a portable target system will operate from 12 volts DC permitting use with a 12-volt auto battery. A fixed system typically operates from 24 volts.

Rotation calibration

- The time taken for the target units to turn from the “edge-on” position to the “facing” position (or return) is exactly ½ second. This is the standard calibrated target turning time. The target exposure times, facing and edge-on, are, of course, controlled from the wireless remote control transmitter.

Weight

- The weight of the complete Compact Base Turning Target, assembled for use, is 11 lbs.